Building or renovating your home?

The materials you select for your house floor joist system will determine how solid your floors feel underfoot for decades to come.

Many homeowners focus on beautiful finishes and forget about what’s hidden beneath, but this structural foundation deserves just as much attention.

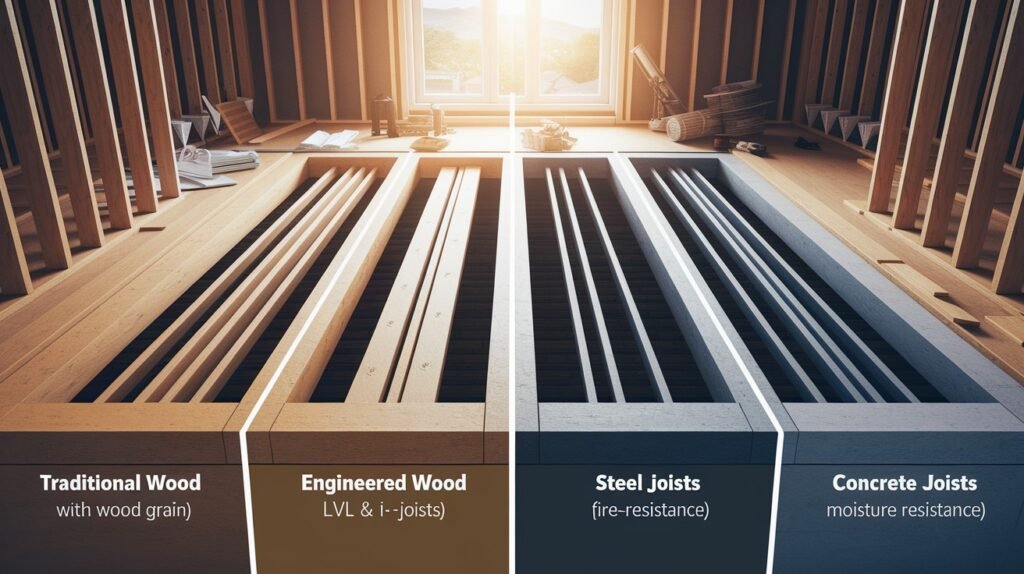

From traditional lumber to modern engineered options, today’s market offers a range of compelling choices.

Each material brings distinct advantages in strength, cost, and longevity. Some excel in moisture-prone areas, while others shine in budget-conscious projects or large open spaces.

The right choice depends on your specific needs, climate, and construction goals.

Let’s examine the top materials available and help you make an informed decision that supports your home’s structural integrity and your peace of mind.

What Are House Floor Joists?

House floor joists are horizontal structural members that form the framework supporting your home’s floors.

These wooden or steel components transfer the weight from floors, furniture, and occupants down to the foundation walls or support beams below.

They create the essential skeleton that keeps floors level, prevents sagging, and maintains structural integrity.

Proper joist installation ensures your floors can handle daily loads while remaining stable and secure for years.

Where Are They Located in a Home?

Floor joists are positioned in several key areas throughout residential construction:

- Basement level – Supporting the main floor above

- Between stories – Creating separation between the first and second floors

- Crawl spaces – Providing foundation support in raised homes

- Attic areas – Supporting upper floor systems in multi-story homes

Difference Between Joists, Beams, and Subflooring

|

Component |

Primary Function |

Size/Dimensions |

Location |

Load Distribution |

|

Joists |

Support floor loads across shorter spans |

2×8 to 2×12 inches typically |

Horizontal, between walls/beams |

Transfer loads to beams/walls |

|

Beams |

Carry major structural loads |

Larger – 4×10+ or steel I-beams |

Span longer distances |

Support multiple joists |

|

Subflooring |

Provide a surface for finish flooring |

¾” plywood or OSB sheets |

Attached to the top of the joists |

Distribute point loads to joists |

Key Factors to Consider When Choosing Joist Materials

Load-Bearing Capacity

The most critical factor is how much weight your joists can safely support. This includes dead loads (the structure itself) and live loads (people, furniture, appliances).

Different materials offer varying strength-to-weight ratios. Engineered lumber often provides superior load capacity compared to dimensional lumber of the same size.

Steel joists excel in high-load applications but require professional calculations. Always consult local building codes and consider future needs when evaluating load requirements.

Moisture Resistance

Exposure to humidity, leaks, or ground moisture can compromise joist integrity over time. Treated lumber offers better protection against rot and decay than untreated options.

Steel joists resist moisture damage but may require rust prevention measures. Engineered wood products vary in moisture tolerance depending on manufacturing processes.

Consider your climate, basement conditions, and potential water exposure when selecting materials for long-term durability.

Cost and Availability

Material costs fluctuate based on market conditions, location, and demand. Dimensional lumber typically offers the most budget-friendly option, while engineered products and steel command higher prices.

Factor in local availability, some materials may require special ordering or longer lead times.

Consider total project costs, including installation complexity, as some materials require specialized tools or expertise that affect labor expenses.

Lifespan and Maintenance Needs

Different materials age at varying rates under normal conditions. Properly treated lumber can last 50+ years with minimal maintenance. Steel joists offer exceptional longevity but may need periodic inspection for corrosion.

Engineered wood products provide consistent performance with minimal warping or shrinkage.

Consider your long-term maintenance preferences and budget when choosing between materials that require regular upkeep versus those offering set-and-forget performance.

Environmental Impact and Sustainability

Construction choices affect environmental footprints through material sourcing, manufacturing processes, and end-of-life disposal.

Sustainably harvested lumber from certified forests supports responsible forestry practices. Engineered products often use smaller trees and wood waste more efficiently.

Steel joists offer recyclability benefits but require energy-intensive manufacturing.

Consider local sourcing options to reduce transportation impacts and support regional economies while meeting your construction goals.

Comparative Table: Material vs. Performance

|

Performance Factor |

Dimensional Lumber |

Engineered Wood (LVL) |

I-Joists |

Steel Joists |

Concrete Joists |

|

Load Capacity |

Moderate (40-50 PSF) |

High (60-80 PSF) |

Good (50-65 PSF) |

Excellent (100+ PSF) |

Superior (150+ PSF) |

|

Maximum Span |

12-16 feet |

20-28 feet |

24-32 feet |

30-40+ feet |

25-35 feet |

|

Initial Cost |

Low ($3-8/LF) |

Moderate ($8-15/LF) |

Moderate ($6-12/LF) |

High ($15-25/LF) |

Very High ($20-35/LF) |

|

Lifespan |

30-50 years |

50+ years |

50+ years |

75-100 years |

100+ years |

|

Moisture Resistance |

Poor-Fair |

Good |

Good |

Excellent |

Excellent |

|

Fire Resistance |

Poor |

Fair |

Fair |

Excellent |

Superior |

|

Installation Ease |

Very Easy |

Easy |

Easy |

Difficult |

Very Difficult |

|

Weight |

Light |

Light-Moderate |

Very Light |

Heavy |

Very Heavy |

|

Maintenance Needs |

Moderate |

Low |

Low |

Very Low |

Minimal |

|

Environmental Impact |

Low-Moderate |

Moderate |

Moderate |

High |

High |

|

Availability |

Excellent |

Good |

Good |

Limited |

Limited |

|

Dimensional Stability |

Poor |

Excellent |

Excellent |

Excellent |

Excellent |

|

Pest Resistance |

Poor |

Good |

Good |

Excellent |

Excellent |

|

Modification Flexibility |

Excellent |

Good |

Fair |

Poor |

Very Poor |

|

Sound Performance |

Fair |

Good |

Good |

Fair |

Excellent |

Performance Rating Scale:

- Poor: Below standard performance, frequent issues

- Fair: Adequate for basic applications

- Good: Meets most residential requirements

- Excellent: Exceeds standard expectations

- Superior: Best-in-class performance

Key Takeaways:

- Best Overall Value: I-Joists offer balanced performance across multiple factors

- Budget Choice: Dimensional lumber for cost-conscious projects

- Premium Performance: Steel and concrete for demanding applications

- Versatility Leader: Engineered wood products provide consistent results

Common Materials Used for Floor Joists

1. Dimensional Lumber (Softwood)

Types:

- Douglas Fir – High strength-to-weight ratio, excellent for structural applications

- Southern Yellow Pine – Strong and affordable, widely available across regions

- Spruce-Pine-Fir (SPF) – Cost-effective option, good for standard residential loads

- Hem-Fir – Lighter weight, suitable for shorter spans and budget projects

Pros and Cons

Traditional lumber offers affordability and easy installation with standard tools. It’s readily available and familiar to most contractors.

However, natural wood can warp, shrink, or develop defects over time. Moisture exposure risks rot and insect damage without proper treatment.

Best Use Scenarios

Ideal for standard residential construction, budget-conscious projects, and areas where contractors have extensive experience with wood framing.

Works well in dry climates and properly ventilated spaces with consistent moisture control.

2. Engineered Wood (LVL, I-Joists)

How It’s Made?

Laminated Veneer Lumber (LVL) bonds thin wood veneers with adhesives under heat and pressure.

I-joists combine engineered lumber flanges with oriented strand board or plywood webs, creating lightweight yet strong structural members through controlled manufacturing processes.

Strength and Span Comparison

Engineered products typically span 25-50% farther than dimensional lumber of equivalent depth.

They maintain consistent strength without natural wood defects. I-joists offer excellent strength-to-weight ratios, while LVL provides superior load-bearing capacity for heavy applications.

Pros and Cons. Benefits include dimensional stability, longer spans, and consistent quality. However, they cost more than dimensional lumber and require special fasteners.

Some products need protection from moisture during construction and may have limited availability in certain regions.

3. Steel Joists

When and Why to Use Them?

Steel joists work best for commercial applications, long spans exceeding wood capabilities, or areas requiring fire resistance.

They’re essential when maximum strength is needed, such as supporting heavy equipment or creating large open spaces without intermediate supports.

Longevity and Resistance

Steel offers superior resistance to warping, shrinking, and pest damage compared to wood alternatives.

Properly coated steel joists can last 100+ years with minimal maintenance. They won’t rot or burn, making them ideal for challenging environmental conditions.

Installation Challenges

Installation requires specialized tools, welding equipment, and experienced contractors. Steel’s thermal properties may cause condensation issues without proper insulation.

Higher material and labor costs often make steel less practical for standard residential applications.

4. Concrete Joists (in Hybrid or Slab Systems)

Use in Modern or High-Load Applications

Concrete joists excel in commercial buildings, multi-story construction, and applications requiring exceptional fire resistance.

They’re commonly used in hybrid systems combining concrete’s strength with other materials for optimal performance in demanding structural situations.

Benefits and Drawbacks:

- Benefits – Superior fire resistance, excellent load capacity, minimal maintenance requirements

- Benefits – Outstanding durability and pest resistance in harsh conditions

- Drawbacks – Heavy weight requires robust foundation support systems

- Drawbacks – Higher installation costs and specialized equipment needs

- Drawbacks – Limited flexibility for future modifications or utility routing

Cost Breakdown of Floor Joist Materials

|

Material Type |

Upfront Material Costs (per linear foot) |

Long-Term Maintenance & Replacement |

Labor & Installation Expenses |

|

Dimensional Lumber |

$3 – $8 |

Low-Moderate: Periodic inspections, potential repairs after 30-40 years, termite treatment costs |

Low: Standard carpentry tools, familiar installation process, $2-4 per sq ft |

|

Engineered Wood (LVL) |

$8 – $15 |

Low: Minimal maintenance, 50+ year lifespan, occasional moisture protection updates |

Low-Moderate: Standard tools, careful handling required, $3-5 per sq ft |

|

Engineered I-Joists |

$6 – $12 |

Very Low: Consistent performance, minimal warping, 50+ year expected life |

Low-Moderate: Special hangers needed, precise cutting, $3-5 per sq ft |

|

Steel Joists |

$15 – $25 |

Very Low: Rust prevention coating every 15-20 years, potential corrosion inspection |

High: Specialized equipment, welding expertise, $8-12 per sq ft |

|

Concrete Joists |

$20 – $35 |

Minimal: Virtually maintenance-free, 75+ year lifespan, occasional sealant touch-ups |

Very High: Heavy equipment, specialized installation, $15-25 per sq ft |

Additional Cost Considerations

Hidden Expenses by Material:

- Lumber: Potential callback costs for warping or settling issues

- Engineered Wood: Higher fastener costs, special adhesives for some applications

- Steel: Insulation requirements, condensation prevention measures

- Concrete: Foundation reinforcement, crane rental for installation

Regional Price Variations: Material availability significantly impacts costs. Lumber prices fluctuate seasonally, while specialty materials may require shipping charges in remote areas.

Conclusion

Selecting the right house floor joist material requires balancing performance, budget, and project requirements.

Dimensional lumber remains the go-to choice for standard residential construction due to its affordability and familiar installation process.

Engineered wood products offer superior consistency and longer spans, making them ideal for modern construction needs.

Steel joists excel in commercial applications or when maximum strength is required, while concrete joists provide unmatched durability for heavy-duty applications.

Consider your specific circumstances: climate conditions, load requirements, budget constraints, and long-term maintenance preferences.

Most residential projects benefit from engineered I-joists or LVL lumber, which provide excellent value through improved performance and reduced callbacks.

For specialized applications, consult with structural engineers to ensure proper material selection.

Remember that quality installation matters as much as material choice. Invest in experienced contractors familiar with your selected material to maximize performance and longevity.

Frequently Asked Questions

What’s the most cost-effective joist material for standard residential construction?

Dimensional lumber offers the lowest upfront costs, while engineered I-joists provide better long-term value through superior performance and reduced maintenance needs.

How do I know if my floor joists need replacement?

Look for sagging floors, squeaking sounds, visible cracks, or pest damage. Consult a structural engineer for professional assessment and recommendations.

Can I mix different joist materials in the same project?

Yes, but requires careful engineering calculations to ensure proper load distribution. Different materials have varying deflection rates that must be considered.