Planning a home renovation or new construction project? Interior wall thickness matters more than you think. Getting these measurements wrong can mess up your plans, cost you money, and create severe headaches down the road. Most interior walls measure 4½ inches thick, consisting of 2×4 studs (3½ inches) with ½-inch drywall on each side.

This article covers everything you need to know about interior wall dimensions. You’ll learn standard measurements for different wall types, framing requirements, and how thickness affects your project planning. We’ll also explain when walls might be thicker or thinner than usual.

I’ve worked in construction for over a decade, and I’ve seen too many DIY projects go sideways because someone didn’t account for proper wall thickness. You can trust this information – it comes from real experience, not just textbook knowledge.

By the end of this guide, you’ll know exactly how thick your interior walls should be. No more guessing. No more costly mistakes. Just the facts you need to move forward with confidence.

Standard Interior Wall Thickness Measurements

Getting wall thickness right is crucial for any building project. I’ll break down the exact measurements you need to know.

Typical Residential Interior Wall Dimensions

Most interior walls fall within a standard thickness range of 4 to 6 inches. This isn’t random – it’s based on building codes and practical construction needs. The most common measurement you’ll encounter is 4½ inches thick. This comes from combining a 3½-inch wood frame with ½-inch drywall on both sides. Simple math, but it matters.

In metric terms, non-load-bearing interior walls typically measure 10-12 centimeters thick. If you’re working with metric measurements, this translates to roughly 4-5 inches. Here’s what’s interesting: the “standard” can vary based on your home’s age and construction style. Older homes might have thicker walls due to different building methods.

Breaking Down the Components

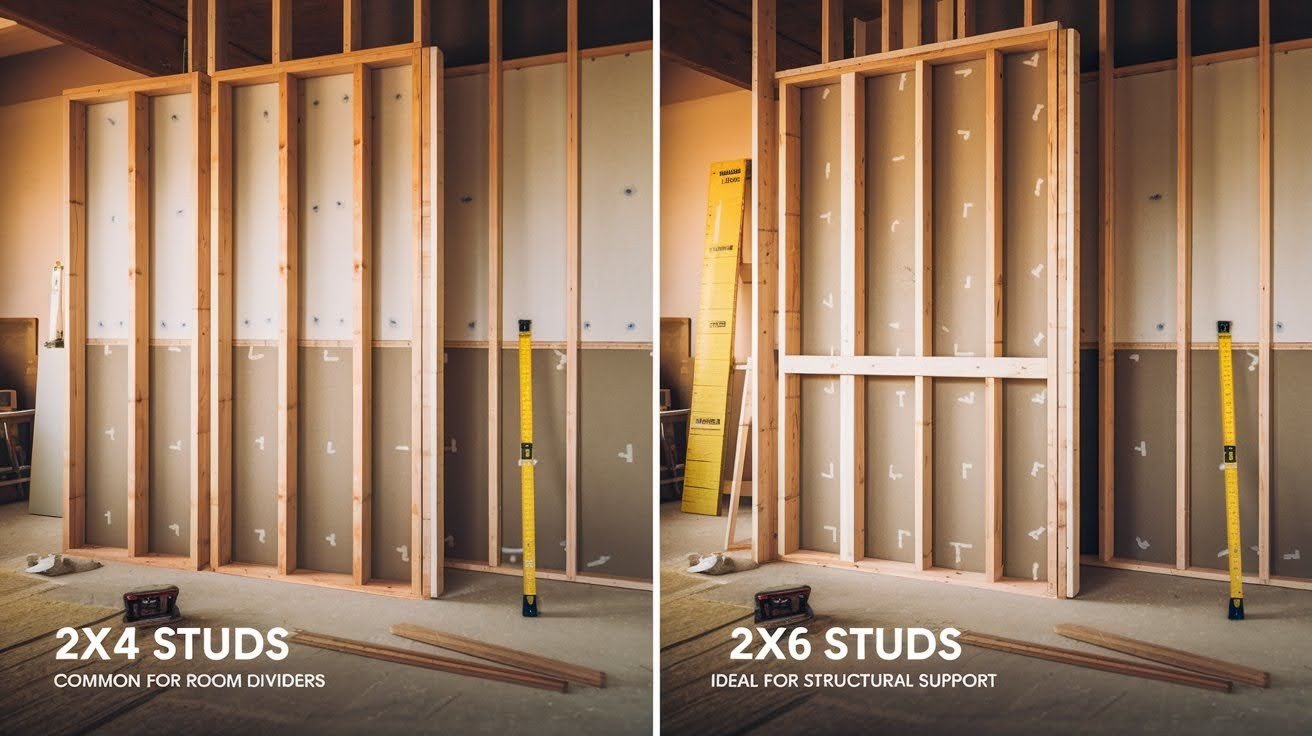

Let me show you exactly how we get that 4½-inch measurement. The 2×4 stud framework forms the backbone of most interior walls. Despite being called “2×4,” the actual width is 3½ inches. This confuses many people, but it’s industry standard.

Drywall thickness adds another inch total. Standard drywall is ½ inch thick, and you need it on both sides of the wall. The total calculation looks like this: 3½ inches (studs) + 0.5 inches (drywall) + 0.5 inches (drywall) = 4½ inches total.

But here’s where it gets tricky. Drywall thickness can vary. Some builders use ⅝-inch drywall, especially in commercial buildings or for fire resistance. This changes your total thickness to 4¾ inches.

Occasionally, you’ll see ¼-inch drywall used for curved walls or repairs. This would give you a thinner 4-inch wall.

Why These Measurements Matter

Room dimensions change based on wall thickness. A room that’s 10 feet by 12 feet on the plans might be smaller once you account for wall thickness. I’ve seen homeowners get frustrated when their furniture doesn’t fit as expected. Thick walls eat up space faster than you think.

Electrical and plumbing installation requires specific clearances. Electricians need to know the exact wall thickness to choose the right outlet boxes and wire runs. Plumbers face similar challenges. Thick walls provide more room for pipes and fixtures, while thin walls limit options.

Furniture placement becomes critical in smaller rooms. That extra inch of wall thickness might mean your couch won’t fit in the planned spot. Understanding these measurements upfront saves time, money, and headaches later.

Different Types of Interior Walls and Their Thickness

Not all interior walls are created equal. Each type serves a different purpose and requires specific thickness measurements.

Non-Load-Bearing Partition Walls

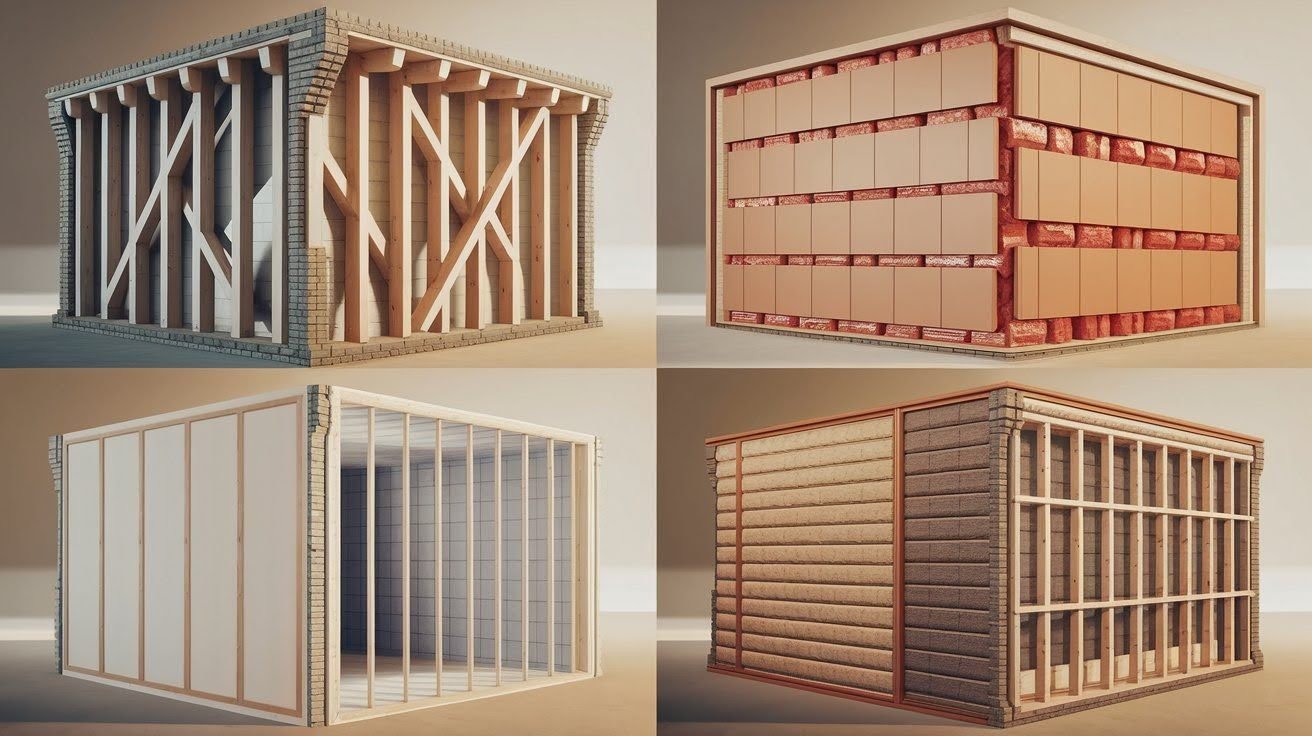

These walls exist for one main reason: to divide rooms. They don’t support any structural weight from above. Standard thickness runs 4-5 inches. This gives you enough space for basic construction without wasting square footage.

Most partition walls use 2×4 studs with standard drywall on both sides. It’s the most cost-effective approach for simple room separation. Here’s the bonus: space efficiency. Thinner partition walls mean larger rooms. Every inch counts in smaller homes.

I always recommend these for closets, bathrooms, and bedroom divisions. They get the job done without overbuilding.

Load-Bearing Interior Walls

These walls carry serious weight. They support floors, ceilings, and sometimes the entire structure above.

The thickness range jumps to 6-12 inches (15-30 centimeters). The extra thickness isn’t just for show – it’s for strength.

Enhanced framing becomes necessary. Instead of 2×4 studs, you might need 2×6 studs or engineered lumber for heavy loads. But here’s the catch. Engineering requirements kick in for load-bearing walls. You can’t just build them thicker and call it good.

A structural engineer needs to approve the design. I’ve seen DIY projects fail because someone assumed a thick wall was automatically strong enough. Don’t make that mistake.

Specialized Interior Walls

Some walls need extra thickness for specific functions. Soundproof walls require additional space for insulation and multiple drywall layers. These often measure 6-8 inches thick.

Utility walls house plumbing and electrical systems. Kitchen and bathroom walls frequently need a 6-inch thickness to accommodate pipes and wire runs. Fire-rated walls must meet safety codes. These walls often include special materials and construction methods that increase thickness.

The materials matter as much as the measurements. Fire-rated walls might use Type X drywall, which is thicker than standard drywall. Understanding these differences helps you plan better and avoid costly surprises during construction.

Construction Materials and Their Impact on Thickness

The materials you choose directly affect your wall thickness. Let me break down how each option changes the final measurements.

Wood Frame Construction

Standard 2×4 lumber measures 3½ inches in actual width. This surprises many people who expect a full 4 inches. 2×6 lumber gives you 5½ inches of actual width. I recommend this for load-bearing walls or when you need extra space for insulation.

Here’s the trade-off: 2×4 lumber costs less and takes up less room. However, 2×6 lumber offers better strength and insulation properties. 2×6 construction works well for exterior walls and structural applications. For basic room dividers, 2×4 lumber usually does the job.

Drywall and Finishing Materials

Standard ½-inch drywall is the most common choice. It’s affordable and easy to work with.

⅝-inch drywall becomes necessary for fire-rated walls. This extra thickness helps slow fire spread between rooms. But wait, there’s more to consider.

Plaster alternatives can change your thickness significantly. Some textured finishes add another ¼ inch or more to your wall. Finishing materials like tile backer board or wainscoting increase overall thickness. I’ve seen bathroom walls reach 6 inches thick after adding all the layers.

Alternative Construction Methods

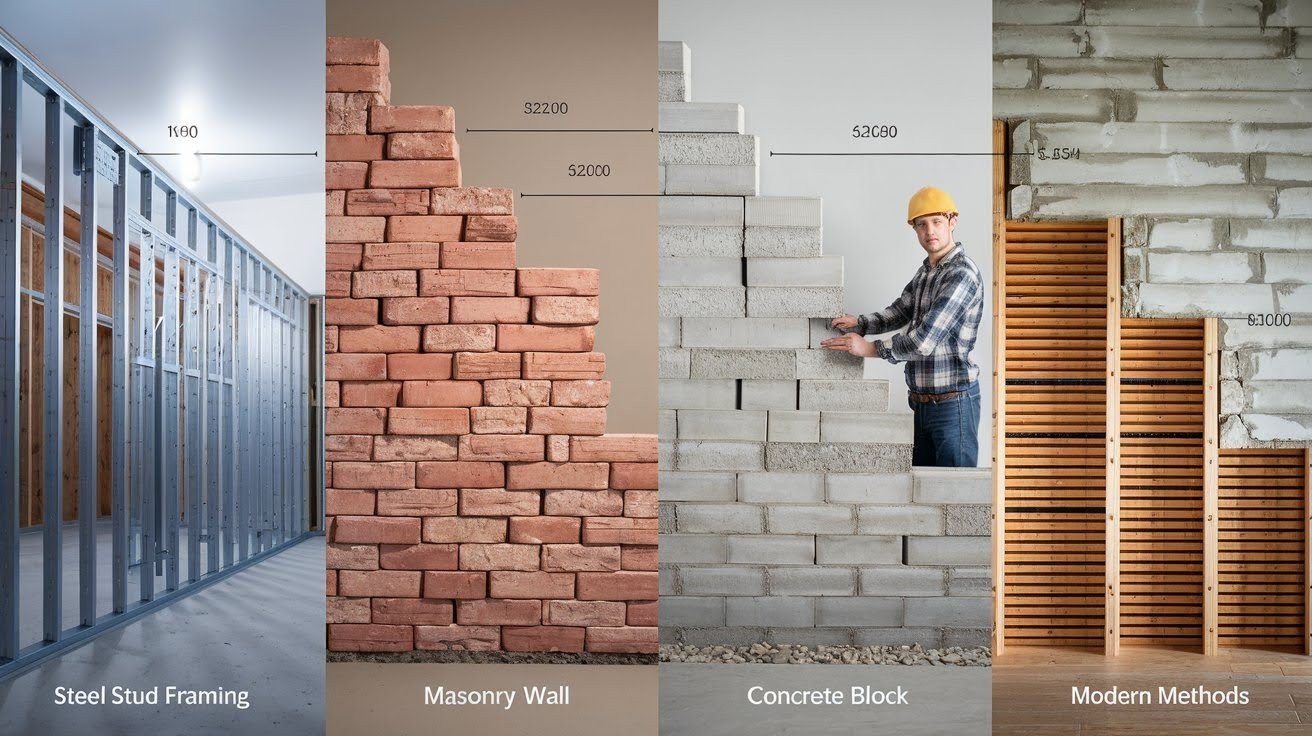

Steel stud framing offers different thickness options. Steel studs come in 2½-inch, 3½-inch, and 6-inch widths. Masonry interior walls in older buildings often measure 8-12+ inches thick. These walls were built to last, but they eat up serious floor space.

Concrete block interior walls also run 8-12+ inches thick. You’ll find these in basements and commercial buildings. Modern building techniques keep changing the game. Insulated concrete forms and structural insulated panels create walls with different thickness requirements.

Here’s what I’ve learned: newer methods often prioritize efficiency over thickness. But older construction methods valued durability over space. Understanding these material choices helps you plan better and avoid surprises during your project.

Factors That Determine Interior Wall Thickness

Several key factors control how thick your interior walls need to be. Understanding these helps you make smart building decisions.

Structural and Code Requirements

Load-bearing walls always need more thickness than simple partition walls. The difference can be significant, sometimes doubling the required thickness.

Fire safety regulations play a huge role in wall thickness. Fire-rated walls between garages and living spaces often require thicker construction with special materials.

Local building codes set minimum thickness requirements. These vary by location, so check with your local building department before starting any project.

Here’s something important: regional variations exist in building standards. What works in Florida might not meet requirements in Alaska. I always recommend checking local codes first. It saves headaches later.

Functional Requirements

Sound insulation needs can drastically increase wall thickness. A standard 4½-inch wall might need to become 6-8 inches thick for proper sound control. Thermal insulation requirements for interior walls depend on your climate zone. Walls separating heated and unheated spaces need extra thickness for insulation.

Utility accommodation often determines wall thickness. Plumbing walls in kitchens and bathrooms frequently need a 6-inch thickness to fit pipes and fixtures properly. But here’s where it gets interesting.

Special applications require custom solutions.

Music rooms need thick walls for sound isolation. Home theaters often require 8-10 inch-thick walls with special insulation. HVAC systems also affect wall thickness. Walls containing ductwork need extra depth to accommodate airflow systems.

The key is planning. Functional requirements often override standard thickness measurements. I’ve seen projects where homeowners had to rebuild walls because they didn’t account for these functional needs upfront. Always consider what the wall needs to do, not just what it needs to support.

Measuring and Planning for Interior Wall Thickness

Getting accurate measurements is crucial for any wall project. Here’s how to do it right.

How to Measure Existing Walls

Remove an outlet cover to get the most accurate measurement. This exposes the wall’s cross-section and shows you the actual thickness. Use a tape measure from one side of the wall to the other. Include all layers: drywall, studs, and finishing materials.

Check multiple locations along the same wall. Thickness can vary, especially in older homes.

Here’s a pro tip: wall thickness often reveals construction type. A 4½-inch wall likely uses 2×4 framing, while a 6½-inch wall probably uses 2×6 framing.

Load-bearing walls typically measure thicker than partition walls. But don’t always assume verify with a structural engineer.

Planning New Interior Walls

Select the thickness based on the wall’s job. Simple room dividers need 4½ inches. Utility walls need 6 inches or more. Space planning becomes critical in smaller rooms. Every inch of wall thickness reduces your usable floor space.

Match existing wall thickness during renovations. This keeps doorways and transitions looking clean and professional. But here’s when to break that rule.

Choose thicker walls for bathrooms, kitchens, and mechanical rooms. These spaces need extra room for pipes and electrical systems. Sound control applications require thicker walls.

Home offices and bedrooms benefit from 6-8 inch thick walls for noise reduction. I always recommend planning wall thickness early in the design process. Changing it later costs time and money.

Conclusion

Now you know exactly how thick interior walls are in most homes, typically 4½ inches for standard partition walls and up to 12 inches for load-bearing or specialized applications. You’re ready to move forward with confidence.

Whether you’re planning a renovation, buying materials, or working with contractors, you have the measurements and knowledge needed to make wise decisions. Remember that wall thickness affects everything from room size to utility placement.

Taking time to plan properly saves money and prevents problems later. Have questions about your specific project? Drop a comment below, and I’ll help you figure out the right wall thickness for your situation. Good luck with your building project!

Frequently Asked Questions

How thick are interior walls in most homes?

Most interior walls measure 4½ inches thick, consisting of 2×4 studs (3½ inches) with ½-inch drywall on each side.

What’s the difference between load-bearing and non-load-bearing wall thickness?

Non-load-bearing walls are typically 4-5 inches thick, while load-bearing walls range from 6-12 inches to support structural weight.

Do all interior walls have the same thickness?

No. Wall thickness varies based on purpose: partition walls (4½ inches), utility walls (6+ inches), and soundproof walls (6-8 inches).

How do I measure my existing interior wall thickness?

Remove an electrical outlet cover and measure from one side to the other, including all layers of drywall and framing.

Why does interior wall thickness matter for renovations?

Wall thickness affects room dimensions, furniture placement, electrical installation, and matching existing construction during renovations.