You’re standing in the lumber aisle, confused. Poplar feels soft, but everyone calls it hardwood. What’s the truth? This question trips up many woodworkers. The answer isn’t what you’d expect.

Here’s what you’ll learn: Why poplar is scientifically a hardwood, how it compares to other woods on the hardness scale, when to use poplar in your projects, and why it feels so different from oak or maple.

I’ve spent years working with different wood types. This guide gives you straight facts – no confusing jargon or sales pitches. You’ll understand Poplar’s true nature by the end. More importantly, you’ll know exactly when to choose it for your next project.

The short answer? Yes, poplar is a hardwood. But the full story is much more interesting. Let’s clear up this confusion once and for all.

Understanding Wood Classification Fundamentals

Wood classification confuses many people because it’s based on tree biology, not actual hardness. Scientists classify trees by reproduction methods, creating misleading “hardwood” and “softwood” categories.

The Science Behind Hardwood vs Softwood Classification

Here’s where things get interesting. The wood industry doesn’t classify trees by how hard they feel. Scientists use a different system entirely. They look at how trees reproduce and grow. It’s all about biology, not touch.

Deciduous trees are called hardwoods. These trees lose their leaves every fall. Think oak, maple, and cherry. Scientists call them angiosperms because they have flowers and produce seeds in fruits.

Coniferous trees are called softwoods. These trees keep their needles year-round. Pine, fir, and cedar fit here. Scientists call them gymnosperms because their seeds grow in cones.

But here’s the kicker. Physical hardness has nothing to do with classification. A “softwood” pine board can be harder than a “hardwood” poplar board. Confusing? Absolutely. The names stick around because that’s how the industry started. We’re stuck with misleading terms that trip up everyone.

Common Misconceptions About Wood Categories

Most people assume hardwood means hard. I get it. The name makes perfect sense. But wood classification doesn’t work that way. Let me give you some examples that’ll blow your mind:

“Soft” Hardwoods: Basswood (410 Janka rating), Poplar (540 Janka rating), Aspen (350 Janka rating). “Hard” Softwoods: Yellow cedar (580 Janka rating), Douglas fir (700 Janka rating), Southern pine (690 Janka rating).

See the problem? Some softwoods are harder than hardwoods. The terminology misleads everyone, from weekend DIYers to professional carpenters. This confusion costs people money. They buy expensive “hardwood” thinking it’s always stronger. Sometimes, cheaper “softwood” would work better for their project.

Poplar’s True Classification

Poplar is scientifically classified as a hardwood despite feeling soft. Its deciduous nature and light weight create confusion, making people question its true hardwood classification.

Scientific Evidence

Poplar is 100% hardwood. No debate here. The science is crystal clear. Poplar belongs to the genus Populus. All Populus trees are deciduous. They lose their leaves every autumn without fail.

This makes poplar an angiosperm. Angiosperms are flowering plants that produce seeds in fruits. Every angiosperm tree gets classified as hardwood. You can verify this yourself. Watch any poplar tree through the seasons. Spring brings fresh green leaves. Summer shows full foliage. Fall turns those leaves yellow before they drop. Winter reveals bare branches.

That annual cycle proves the poplar’s deciduous nature. No coniferous tree behaves this way.

Physical Properties That Create Confusion

Now I understand why people get confused about poplar. It doesn’t feel like other hardwoods. Poplar weighs much less than oak or maple. Pick up a poplar board, then grab an oak board of the same size. The difference is obvious. Poplar feels almost hollow by comparison.

The texture throws people off, too. Run your hand across the poplar’s surface. It feels smooth and soft. Compare that to the rough, dense feel of hickory or ash. Poplar’s grain looks different as well. You’ll see straight, even lines running through the wood. No wild patterns or dramatic figures. Just clean, simple grain that looks almost boring.

Color-wise, poplar stays neutral. Most pieces range from creamy white to light tan. Sometimes you’ll spot greenish streaks, but they’re subtle. Nothing like the rich browns of walnut or the warm reds of cherry. These properties make poplar feel like softwood. But feelings can be wrong.

Poplar’s Unique Properties and Characteristics

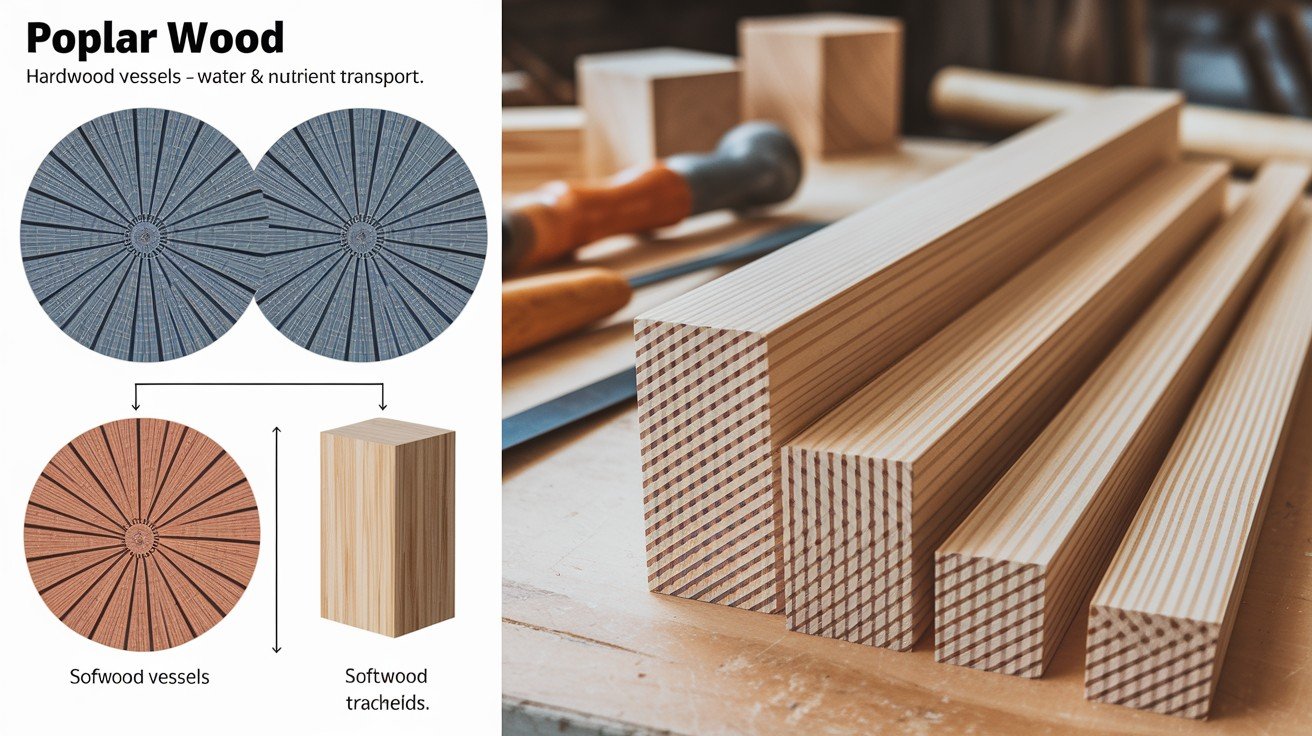

Poplar’s microscopic structure reveals hardwood vessel elements, while its straight grain and uniform texture make it exceptionally workable. These properties create predictable, consistent performance for woodworkers.

Physical Attributes

Under a microscope, poplar shows its true hardwood nature. The cellular structure tells the real story. Poplar has vessel elements throughout its wood. These tiny tubes transport water and nutrients. Only hardwoods have this feature. Softwoods use different cells called tracheids instead.

The grain runs remarkably straight. I’ve worked with thousands of poplar boards. Most show perfectly parallel grain lines from end to end. This makes cutting and shaping incredibly predictable. Texture stays fine and uniform throughout. No sudden changes in density. No random knots are appearing everywhere. Just consistent, workable wood from top to bottom.

This combination creates ideal working conditions. You can predict exactly how popular will behave under your tools will behave.

Workability Features

Poplar cuts like butter with sharp tools. I’ve never met a saw that struggled with poplar. Hand saws, circular saws, table saws – they all slice through cleanly. Shaping poplar takes minimal effort. Routers glide through without burning or chipping. Chisels pare off shavings effortlessly. Even hand planes work smoothly across the surface.

Here’s something that surprises many woodworkers: Poplar holds screws and nails incredibly well. The soft texture doesn’t mean weak holding power. Those vessel elements grip fasteners tightly. Splitting rarely happens with poplar. I’ve driven thousands of nails without pre-drilling. The fine-grain structure absorbs impact without cracking. Try that with oak and you’ll split boards left and right.

Paint and stain love the poplar’s surface. The even grain accepts finishes uniformly. No blotchy spots or uneven coverage. This makes poplar perfect for painted projects where you want smooth, professional results.

Practical Applications of Poplar Wood

Poplar excels in furniture internals, structural frames, and painted projects where appearance doesn’t matter. Its affordability and workability make it ideal for cost-effective construction.

Furniture Manufacturing

I use poplar constantly for furniture internals. Drawer sides, backs, and bottoms work perfectly in poplar. You’ll never see these parts anyway, so why pay extra for pretty wood? Chair and sofa frames often use poplar construction. The wood provides plenty of strength for structural support. Upholstery covers everything, making appearance irrelevant.

Poplar substitutes beautifully for expensive hardwoods. Stain it dark, and most people can’t tell the difference from walnut. Paint it and it looks identical to maple or birch. You save serious money without sacrificing quality. Cabinet makers love poplar for face frames. The smooth surface takes paint perfectly. No grain patterns showing through. No color variations are creating problems. Just clean, consistent results every time.

Home Improvement Projects

Trim work showcases poplar’s strengths perfectly. Baseboards, door casings, and crown molding all benefit from poplar’s workability. It cuts cleanly, joints tightly, and paints beautifully. Interior paneling projects favor poplar consistently. The light color provides an excellent base for any finish. Stain it to match existing woodwork or paint it for a fresh, modern look.

Budget renovations rely heavily on poplar. You get hardwood quality at softwood prices. This makes expensive projects suddenly affordable. Contractors choose poplar for painted millwork. Why pay extra for wood that’s getting covered anyway? The result looks identical to premium species.

Why These Applications Prove Its Hardwood Status?

Think about where you see poplar used. These applications typically demand hardwood performance. Furniture manufacturers wouldn’t risk their reputation on weak wood. They choose poplar because it provides hardwood strength at competitive prices. Those drawer sides need to handle daily use for decades.

Structural integrity matters in frame construction. Sofas and chairs endure constant stress from human weight and movement. Poplar handles these loads without failing. That’s hardwood performance in action. Cabinet face frames require dimensional stability. Wood movement can ruin cabinet doors and drawers. Poplar stays put better than many traditional hardwoods. This proves its structural reliability.

The durability speaks for itself. I’ve seen poplar furniture components last 50+ years. Softwoods rarely achieve this longevity under constant use. Poplar’s hardwood genetics show through its performance.

Conclusion

Now you know the truth. Poplar is a hardwood – science proves it. The confusion comes from its soft feel and light weight.

Remember the key facts. Poplar comes from deciduous trees, making it botanically a hardwood. Its Janka rating of 540 puts it above most softwoods. It’s perfect for painted projects, furniture frames, and beginner woodworking.

Don’t let the soft texture fool you. Poplar offers real strength where it counts. It’s affordable, easy to work with, and widely available.

Your next step? Try poplar on your next indoor project. You’ll appreciate its workability and cost savings. Just remember to paint or stain it for the best results.

Poplar proves that hardwood doesn’t always mean hard to work with.

Frequently Asked Questions

Is poplar stronger than pine?

Yes, poplar has a higher Janka rating (540) than pine (380), making it stronger despite both being easy to work with.

Can poplar be used for outdoor projects?

No, poplar lacks natural weather resistance and requires treatment or sealing for any outdoor applications to prevent decay.

Why is poplar so cheap compared to oak?

Poplar grows faster than oak, is more abundant, and has less attractive grain, making it economical for utility applications.

Does poplar wood split easily when nailing?

No, poplar rarely splits when nailing due to its fine-grain structure, though pre-drilling is still recommended practice.

Is poplar good for beginner woodworkers?

Yes, poplar’s softness, straight grain, and forgiving nature make it excellent for learning basic woodworking skills and techniques.