Choosing the right insulation for your home can feel overwhelming. Two popular options dominate the market: Rockwool and spray foam. But which one works best for your specific situation?

You’re probably wondering about costs, performance, and installation requirements. Maybe you’re concerned about noise from neighbors or want to cut your energy bills. We get it.

Here’s what you’ll learn in this guide: Real-world performance comparisons, actual costs (not just estimates), installation requirements for both materials, and which option works best for different situations.

We’ve analyzed data from real homeowners, contractors, and building professionals. No marketing fluff or biased recommendations here. Just honest comparisons based on actual results.

By the end of this article, you’ll know exactly which insulation makes sense for your home, budget, and goals. No more second-guessing or expensive mistakes.

Let’s break down the facts so you can make a confident decision.

Understanding the Basics

|

Feature |

🪨 Rockwool |

💨 Spray Foam |

|

📋 Material Base |

Volcanic rock & steel slag 100% natural materials |

Polyurethane chemicals Petroleum-based synthetic |

|

🏗️ Manufacturing |

Heat rock to 3,000°F Spin into fibers Form into batts/boards |

Two chemicals mix in the spray gun Expands 100x the original size Hardens in minutes |

|

📐 Types Available |

Batts, boards, loose-fill Various thicknesses (2.5″, 3″, 3.5″) |

Open-cell (lighter, cheaper) Closed-cell (denser, higher R-value) |

|

🎯 Primary Strength |

Sound absorption Fire resistance Chemical-free |

Air sealing Gap filling Higher R-value per inch |

|

⚡ Installation |

DIY-friendly Cut with a bread knife No special equipment |

Professional only Specialized equipment Safety gear required |

|

🔥 Fire Resistance |

Naturally fireproof Withstands 1,000°C No toxic gases are produced when heated |

Can be treated with retardants Burns at lower temperatures May release gases |

|

🌱 Environmental |

Natural materials Recyclable No off-gassing |

Petrochemical base 2-3 years off-gassing High energy efficiency benefit |

|

⏱️ Installation Time |

Weekend DIY project Immediate occupancy |

1-2 days of professional work 24-48 hour wait before occupancy |

Performance Comparison

Now let’s see how these materials perform in your home.

R-Value and Thermal Efficiency

R-value measures how well insulation resists heat flow. Higher numbers mean better insulation.

Spray foam wins the R-value game decisively:

- Spray foam: 6 to 7 per inch

- Rockwool: 3 to 4 per inch

What does this mean for you? You need twice as much Rockwool to match spray foam’s thermal performance.

In extreme climates, this difference matters a lot. Cold winters and hot summers put serious stress on your heating and cooling systems.

But here’s where it gets interesting. Spray foam doesn’t just insulate – it seals air leaks, too.

Air leaks are energy killers. They can account for 25-40% of your energy loss. Traditional insulation does nothing about this. Spray foam stops it completely. Rockwool, on the other hand, performs consistently over time. It won’t settle or lose effectiveness. You get steady, reliable insulation for decades.

The climate factor is huge. In moderate climates, Rockwool’s lower R-value might be perfectly adequate. In extreme climates, spray foam’s superior performance pays off quickly.

Soundproofing Performance

Both materials reduce noise, but in different ways.

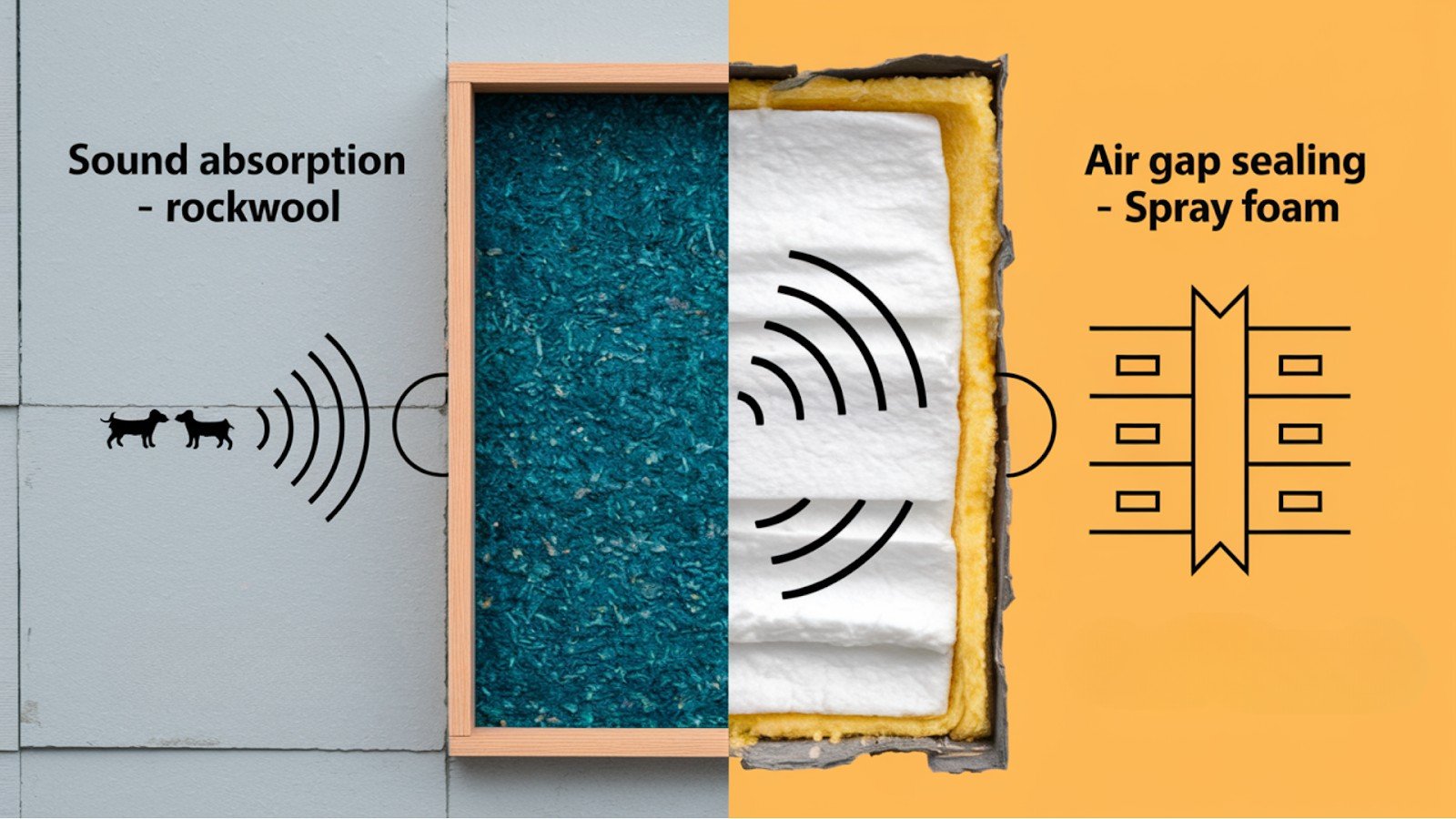

Rockwool excels at absorbing sound waves. Its dense, fibrous structure traps sound energy and converts it to tiny amounts of heat. This makes it excellent for reducing sound transmission through walls and ceilings.

Real-world example: One homeowner installed Rockwool specifically to deal with barking dogs down the road. The results were impressive – significant noise reduction in their 2×6 wall construction.

Spray foam takes a different approach. It doesn’t absorb sound as well as Rockwool. But it seals every gap where noise can sneak through.

Think about it this way: Rockwool is like a sound sponge. Spray foam is like acoustic caulk.

For maximum noise control, some contractors use both materials together. Spray foam seals the gaps, then Rockwool absorbs the remaining sound.

The verdict? If noise reduction is your main concern, Rockwool has a slight edge. If you want good soundproofing plus thermal performance, spray foam delivers both.

Cost Analysis

Let’s talk money. The upfront costs are dramatically different.

Initial Investment Comparison

The price difference is significant:

Spray foam costs: $2.00 to $9.00 per square foot

- Open-cell: $2.00 to $5.00 per square foot

- Closed-cell: $4.00 to $9.00 per square foot

Rockwool costs: $0.62 to $1.10 per square foot

That’s a 3 to 8 times difference. For a typical home, we’re talking thousands of dollars.

But wait – there’s more to consider.

Spray foam requires professional installation. You can’t DIY this stuff. The equipment costs tens of thousands of dollars, and improper installation can be dangerous.

Rockwool? You can install it yourself with basic tools. An electric bread knife cuts it perfectly. No special training needed.

Professional installation adds $2-4 per square foot to any insulation project. With Rockwool, you can skip this cost entirely.

Long-Term Value Assessment

Here’s where spray foam starts to make sense financially.

The superior R-value and air sealing translate to real energy savings. Many homeowners see 20-30% reductions in heating and cooling costs.

Let’s do the math on a typical home:

- Annual energy bill: $2,400

- Spray foam savings: 25% = $600 per year

- Rockwool savings: 15% = $360 per year

- Difference: $240 per year

Over 20 years, that’s $4,800 in additional savings. This often justifies the higher upfront cost in extreme climates.

But here’s the catch: These savings depend heavily on your climate and current insulation levels.

In moderate climates, the payback period stretches to 15-20 years. That’s assuming energy prices don’t change, which they always do.

Maintenance is minimal for both materials. Neither settles nor degrades significantly over time. Both should last 50+ years with proper installation.

Installation and Practical Considerations

Installation differences are night and day.

Installation Requirements

Spray foam installation is complex and dangerous.

You need:

- Specialized spray equipment

- Protective gear (full body suits, respirators)

- Proper ventilation

- Temperature and humidity control

- Professional training

The process takes 1-2 days for a typical home. You’ll need to leave during the application and for 24-48 hours afterward.

Surface preparation is critical. Any dust, moisture, or debris affects adhesion. One mistake can compromise the entire installation.

Rockwool installation is straightforward.

You need:

- Electric bread knife or insulation knife

- Measuring tape

- Staple gun (for some applications)

- Dust mask

Most homeowners can insulate their entire home in a weekend. Cut to fit, stuff in place, and you’re done.

No special ventilation required. No waiting periods. You can live in your home throughout the entire installation.

Safety and Health Factors

This is where things get serious.

Spray foam off-gassing is a real concern. Despite manufacturer claims of 24-48 hour curing, real-world experience shows 2-3 years of detectable emissions.

The problem? Perfect mixing is nearly impossible in real installations. Temperature, humidity, and equipment variations all affect the chemical reaction.

In small spaces like buses or tiny homes, this becomes a major health consideration. One builder specifically chose Rockwool to avoid these risks entirely.

Rockwool is chemical-free. No off-gassing. No curing time. You can occupy the space immediately after installation.

Fire resistance is another factor:

- Rockwool: Withstands temperatures up to 1,000°C without melting

- Spray foam: Can be treated with fire retardants, but burns at lower temperatures

For areas around electrical components or high-heat applications, Rockwool provides superior fire safety.

Best Applications and Recommendations

The right choice depends on your specific situation.

When to Choose Rockwool

Rockwool makes sense when:

Noise reduction is your priority. Recording studios, home offices, and bedrooms near busy roads benefit from Rockwool’s superior sound absorption.

You’re budget-conscious. The 3-8x cost difference matters, especially for large projects.

You want to DIY. Weekend warriors can tackle Rockwool installation without professional help.

Fire safety is critical. Areas around furnaces, electrical panels, or fireplaces benefit from Rockwool’s natural fire resistance.

You live in a moderate climate. When extreme temperatures aren’t a factor, Rockwool’s lower R-value may be adequate.

You’re health-conscious. Chemical-sensitive individuals prefer Rockwool’s zero off-gassing profile.

When to Choose Spray Foam

Spray foam excels in specific situations:

Extreme climate conditions. Northern climates with harsh winters or southern regions with brutal summers benefit from spray foam’s superior R-value and air sealing.

Maximum energy efficiency is required. Net-zero homes and high-performance buildings often specify spray foam.

You’re dealing with irregular surfaces. Crawl spaces, rim joists, and curved areas are perfect for spray foam’s gap-filling properties.

Air sealing is critical. Older homes with lots of air leaks see dramatic improvements with spray foam.

Long-term ownership is planned. The payback period makes sense if you’ll stay in the home 10+ years.

Professional installation is acceptable. You’re comfortable with the cost and complexity of professional installation.

You can tolerate off-gassing. Either you’re not chemically sensitive, or you can vacate during the curing period.

Conclusion

The bottom line: Both Rockwool and spray foam have their place, but your specific needs determine the winner.

Choose Rockwool if you’re on a budget, prioritize soundproofing, or want a DIY-friendly option. It’s chemical-free and performs well in moderate climates.

Pick spray foam for extreme climates where energy savings justify the higher cost. Its superior R-value and air sealing capabilities pay off long-term, despite the 3-8x price difference.

Don’t ignore the health factor. Spray foam’s 2-3 year off-gassing period matters in small spaces. Rockwool offers immediate occupancy without concerns.

Your climate, budget, and health priorities should guide your decision. Neither option is universally better – it’s about finding the right fit for your home and situation.

Make your choice based on facts, not marketing hype.

Frequently Asked Questions

Which is better for soundproofing?

Rockwool slightly outperforms spray foam for pure sound absorption, but spray foam provides better overall noise control through gap sealing.

Is spray foam worth the extra cost?

Yes, in extreme climates where energy savings from superior R-value and air sealing justify the 3-8x higher initial investment cost.

Can I install either material myself?

Rockwool is DIY-friendly and cuts easily, while spray foam requires professional installation due to specialized equipment and safety concerns.

Which material lasts longer?

Both materials are durable, but Rockwool maintains consistent performance without settling, while spray foam provides permanent air sealing properties.

Are there health concerns with either option?

Rockwool is chemical-free with no off-gassing, while spray foam can emit VOCs for 2-3 years after installation in real-world conditions.